Introduction

Tactile indicators are a functional necessity for public safety and accessibility. However, UV-induced discoloration can compromise both their functionality and aesthetics. In this blog, we’ll explore the causes of this discoloration, focusing on the differences between engineered and standard polyurethane.

The Importance of Colour in Tactiles

Colour is not just an aesthetic choice; it’s a functional necessity. The right colour contrast can significantly improve visibility, thereby enhancing safety and accessibility for individuals with visual impairments.

The Challenge: UV-Induced Discoloration

One of the most common causes of tactile discoloration is UV exposure. This can be particularly problematic for standard polyurethane tactiles, which can yellow over time, affecting both their appearance and functionality.

The Solution: Engineered Polyurethane

Engineered polyurethane is designed to resist UV-induced discoloration, making it an ideal choice for outdoor installations where exposure to sunlight is inevitable. This UV resistance ensures long-lasting colour and effectiveness.

Case Study: The Transformation of Colours

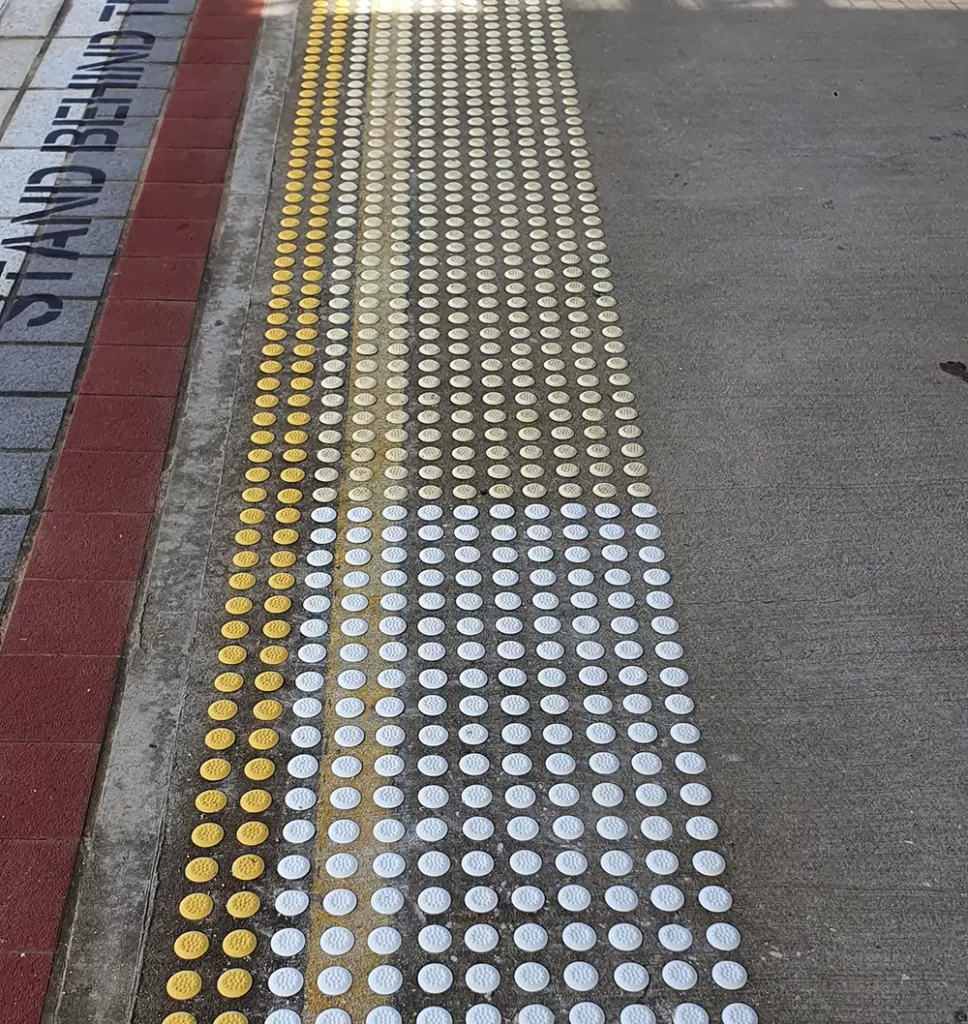

We’ve documented the effects of UV exposure on different types of polyurethane tactiles. Our case study includes photos that show:

- Sky Blue Tactiles: When standard sky blue tactiles yellow due to UV exposure, they turn green.

- White Tactiles: Standard white tactiles turn ivory when they yellow.

These visual examples underscore the importance of choosing the right material for your tactile installations, especially for outdoor use.

At Railtact, we offer engineered polyurethane tactiles that meet the highest standards of safety and durability. These tactiles are designed to resist UV-induced discoloration, making them ideal for any project that requires long-lasting effectiveness and safety.

Conclusion

Understanding the causes and consequences of UV-induced discoloration in polyurethane tactiles can help you make an informed decision for your installations. Our case study clearly illustrates the superior performance of engineered polyurethane, making it the go-to choice for long-lasting, effective tactile indicators.